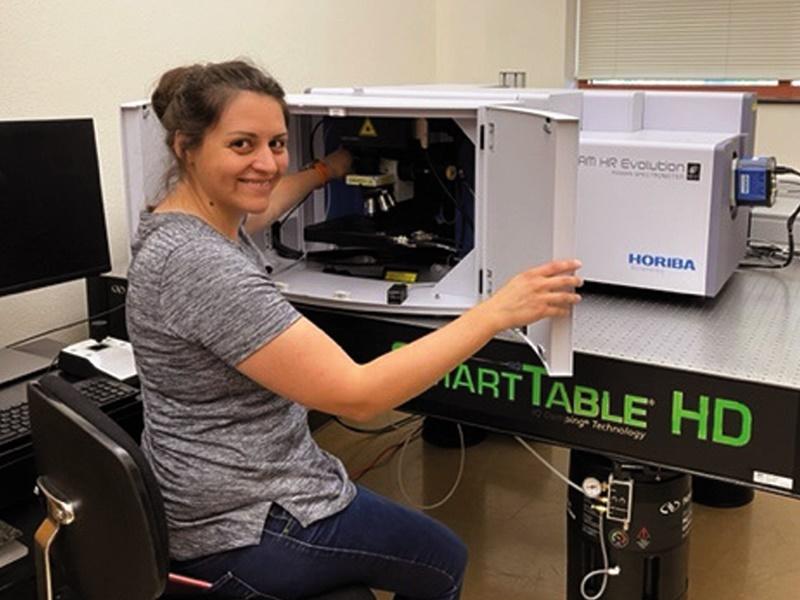

Nicole Hurtig displays the open sample chamber of the new Raman microscope recently installed in a lab within the New Mexico Bureau of Geology and Mineral Resources on the New Mexico Tech campus.

Photo courtesy of New Mexico Tech

While most people observe minerals by their size, shape, color and properties, a new instrument is allowing scientists at New Mexico Tech to look deep inside minerals to understand their composition and how they form.

This powerful new instrument, the high-resolution confocal Raman microscope, is now installed within a New Mexico Bureau of Geology and Mineral Resources lab and is available for mineral and material analyses.

Nicole Hurtig, Ph.D., assistant professor of geochemistry, is the principal investigator on a research team for the lab that includes four Tech faculty from three departments and the Bureau of Geology and Mineral Resources, namely Drs. Alexander Gysi, Nikolai Kalugin, Daniel Jones and Gayan Rubasinghege.

“It’s cool because it’s a state-of-the-art-instrument,” she said. “We will be able to do a broad range of research. There are not a lot of labs that have this kind of setup.

“One of our lasers is in the lower UV range (266 nm), which allows us to also work on organic materials such as hydrocarbons, crude oil, and bitumen, ‘early’ life signatures in old rocks or Martian samples, or organic acids in soils. We really want to push the envelope with its capabilities.”

A $397,000 Major Research Instrumentation (MRI) Grant from the National Science Foundation allowed New Mexico Tech to acquire the new Horiba LabRAM HR Evolution confocal Raman microscope, which will be used for a broad range of applications by faculty and students from the fields of geology; mechanical, material, and mineral engineering; biology and chemistry.

The instrument also will be used by the bureau to assist collectors who are seeking to identify and analyze their minerals.

A key and welcome feature of the Raman is that it can look at a whole specimen — it does not have to be ground up to be analyzed.

“When I talk with mineral collectors, they are so excited,” Hurtig said. “Because we don’t have to destroy the mineral. We can actually do analysis and get a lot of information out of it such as the chemical composition and bonding of a mineral as well as looking at small mineral and fluid inclusions.

“It’s a great tool for characterization of gemstones.”

The Raman has within it a green laser light and an ultraviolet laser that are guided by mirrors to highly concentrate their light on specimens.

The laser light interacts with the mineral, “exciting” the materials, allowing researchers to see the molecules and their binding structure, and producing spectras, which are compared with reference materials for identification and analysis.

One of the Raman’s uses includes a combination with a heating and cooling microthermometry stage — looking at microscopic inclusions of water and gases within minerals providing information on the fluid chemistries and temperatures and pressures at which they formed.

This research has important implications to help guide understanding for looking at processes that make ore deposits that can be mined for valuable resources such as copper, gold, tellurium, rare earth elements (REE), and many others.

Combining the Raman microscope with a hydrothermal diamond anvil cell will allow new research on REE speciation in crustal fluids, led by Alexander Gysi, Laura Waters, and Hurtig and supported by a $2.7 million U.S. Department of Energy Office of Science Basic Energy Science Grant.

Hurtig said that the instrument helps researchers understand how minerals form.

“We want to be better at finding [resources] today,” she said. “How they form is a really important part of the puzzle to solve.”

So far other researchers at Tech have been using the Raman laboratory for their work, but an effort is underway to work through the Mineral Museum to provide mineral analysis as part of an outreach effort.

Contact Hurtig for more information at nicole.hurtig@ nmt.edu.